- DESCRIPTION

- Datasheet

DESCRIPTION

Fosroc Nitoseal PU800 - formerly Expoflex 800

Cures to a tough seal

Abrasion resistant

High modulus

Resistant to chemical, fuel and oil spillage

Easily installed to give a flush finish

Hard, but flexible sealant; resists picking and vandalism

Fosroc Nitoseal PU800 is a two-component gun grade elastomeric sealant for limited movement joints. After mixing, the resultant compound will cure to provide an exceptionally robust seal, while retaining a degree of flexibility. Nitoseal PU800 is abrasion resistant and withstands spillage of fuel oils, mineral acids and vegetable oils. Nitoseal PU800 can be used in joints between 5 mm and 50 mm wide.

Joint surfaces shall be clean, dry and free from contamination. Any voids or gaps at the base of the sealing slot should be filled and a suitable bond breaker should be pushed into construction and contraction joint slots. Where a particularly neat finish is required mask edges of joint before priming (if required) and sealant application.

Where surface shall be subject to submersion or permanently damp, joints should be primed using Fosroc Primer MS2. Decant the entire contents of primer curing agent into the primer base tin and replace lid. Mix thoroughly by shaking tin for 2 minutes. Apply the primer using a clean dry paint brush working well in to ensure complete coverage. Nitoseal PU800 should be applied between 30 minutes and 4 hours after priming. Mixing In cold weather Nitoseal PU800 mixes more easily if stored overnight at room temperature. Transfer the contents of the small tin into the base tin and mix thoroughly using a slow speed drill (300 to 500 rpm) fitted with a Fosroc Sealant

Paddle until a uniform colour is achieved throughout. Immediately after mixing loadthe Nitoseal PU800 into a Fosroc “G” Gun using a follower plate. Extrude the sealant firmly into the joint to ensure complete contact with the joint face.

Nitoseal PU800 should be tooled off flush with adjacent surfaces. A minimum of surface lubrication such as dilute detergent solution may be used to assist the process. Remove masking immediately after tooling.

Clean equipment immediately after use

Heavy duty epoxy urethane joint sealant

PRODUCT USES;

For sealing internal joints subject to heavy loading and abrasion, or where chemical resistance is required. Can be used in factories, warehouses and distribution centres. It is, particularly effective where there is forklift truck traffic. Nitoseal PU800 can also be used where joints would be subject to stiletto heels, shopping centres, podiums etc. It is suitable for use in prisons as an anti-pick sealant for sealing internal partitions, cell doors and windows, fittings and furniture.

PACK SIZE;

2 Litre

COLOUR;

Light Grey

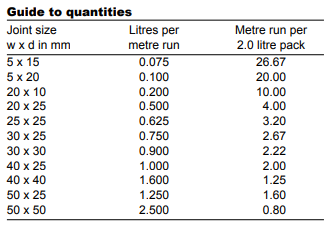

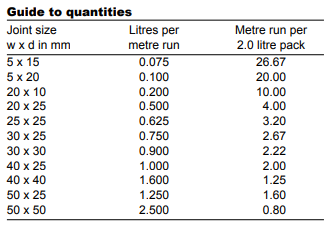

YIELD;

PRODUCT ADVANTAGES;

Cures to a tough seal

Abrasion resistant

High modulus

Resistant to chemical, fuel and oil spillage

Easily installed to give a flush finish

Hard, but flexible sealant; resists picking and vandalism

PRODUCT DESCRIPTION;

Fosroc Nitoseal PU800 is a two-component gun grade elastomeric sealant for limited movement joints. After mixing, the resultant compound will cure to provide an exceptionally robust seal, while retaining a degree of flexibility. Nitoseal PU800 is abrasion resistant and withstands spillage of fuel oils, mineral acids and vegetable oils. Nitoseal PU800 can be used in joints between 5 mm and 50 mm wide.

PRODUCT PREPERATION;

Joint surfaces shall be clean, dry and free from contamination. Any voids or gaps at the base of the sealing slot should be filled and a suitable bond breaker should be pushed into construction and contraction joint slots. Where a particularly neat finish is required mask edges of joint before priming (if required) and sealant application.

PRIMING;

Where surface shall be subject to submersion or permanently damp, joints should be primed using Fosroc Primer MS2. Decant the entire contents of primer curing agent into the primer base tin and replace lid. Mix thoroughly by shaking tin for 2 minutes. Apply the primer using a clean dry paint brush working well in to ensure complete coverage. Nitoseal PU800 should be applied between 30 minutes and 4 hours after priming. Mixing In cold weather Nitoseal PU800 mixes more easily if stored overnight at room temperature. Transfer the contents of the small tin into the base tin and mix thoroughly using a slow speed drill (300 to 500 rpm) fitted with a Fosroc Sealant

MIXING;

Paddle until a uniform colour is achieved throughout. Immediately after mixing loadthe Nitoseal PU800 into a Fosroc “G” Gun using a follower plate. Extrude the sealant firmly into the joint to ensure complete contact with the joint face.

FINISHING;

Nitoseal PU800 should be tooled off flush with adjacent surfaces. A minimum of surface lubrication such as dilute detergent solution may be used to assist the process. Remove masking immediately after tooling.

CLEANING;

Clean equipment immediately after use

Datasheet

Product Reviews

×